Abstract

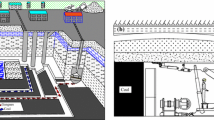

The article gives geological characteristic of ore and enclosing rocks at Sekisovskoe gold deposit. The underground mining involves room-and-pillar and sublevel caving for medium thick ore bodies and shrinkage stoping for thin ore bodies. The use of the solidifying backfill technology is validated. Based on the laboratory research into rheological and strength properties of backfill mixtures, rational backfill compositions are proposed for the said deposit. The technical and economic estimation of backfilling scenarios in Sekisovsky Mine is made for: 1) preparation of backfill in a mixer-activator and gravity flow in pipeline; 2) backfill preparation in a concrete mixer and feed in mine via vertical holes and horizontal mine mixers. Efficient flowsheet is developed for backfill feed from the surface backfill plants. Selection of the rational backfill technology for Sekisovskoe deposit is described.

Similar content being viewed by others

References

Nurseitova, Zh.T, Il’yasov, A.A., and Shaposhnik, Yu.N., Development of Rational and Safe Underground Mining Process for Sekisovskoe Deposit, Vestn. VKGTU., 2014, no. 2.

Bitimbaev, M.Zh., Krupnik, L.A., and Shaposhnik, Yu.N., Teoriya i praktika zakladochnykh rabot pri razrabotke mestorozhdenii poleznykh iskopaemykh (Theory and Practice of Backfill Operations in Mineral Mining Industry), textbook, Almaty: Assots. Vuzov Kazakh., 2012.

GOST 23732-79 as of Jun 07, 1979.

Metodicheskie ukazaniya po opredeleniyu normativnoi prochnosti tverdeyushchei zakladki i otsenke prochnostnykh svoistv iskustvennykh massivov (Guideline on Evaluation of Standard Strength of Solidifying Backfill and Strength Properties of Man-Made Massifs), Saint-Petersburg: VNIMI, 1975.

Rukovodstvo po opredeleniyu normativnoi prochnosti tverdeyushchei zakladki na rudnikakh tsvetnoi metallurgii (Evaluation of Standard Strength of Solidifying Backfill in Non-Ferrous Metal Mines. Manual), Saint-Petersburg, 1993.

Normy tekhnologicheskogo proektirovaniya rudnikov tsvetnoi metallurgii s podzemnym sposobom razrabotki VNTP 37-86 (Underground Non-Ferrous Metal Mine Planning Regulations. VNTP 37-86), Moscow: Mintsvetmet SSSR, 1986.

Normy tekhnologicheskogo proektirovaniya gornodobyvayushchikh predpriyatii s podzemnym sposobom razrabotki (Underground Mine Planning: Recommended Practice), Decree of the Committee for State Monitoring of Emergency Situations and Industrial Safety, Republic of Kazakhstan, no. 46, Dec 4, 2008.

Trebovaniya promyshlennoi bezopasnosti pri vedenii rabot podzemnym sposobom (Safety Requirements for Underground Mining), amended Nov 29, 2011, approved by Minister of Emergency Situations of the Republic of Kazakhstan, Jul 25, 2008, no. 132.

Vremennye pravila okhrany sooruzhenii i prirodnykh ob’ektov ot vrednogo vliyaniya podzemnykh gornykh razrabotok mestorozhdenii rud tsvetnykh metallov (Provisional Regulations on Protection of Structures and Nature from Underground Non-Ferrous Metal Mining Impact), Leningrad: VNIMI, 1986.

Krupnik, L.A. and Shaposhnik, Yu.N., Use of Barren Rocks in Underground Mines, GIAB., 2005, no. 3.

Prokushev, G.A., Ispol’zovanie skal’nykh porod v tekhnologii tverdeyushchei zakladki (Use of Rocks in Solidifying Backfill Preparation), Alma-Ata: Nauka, 1988.

Edil’baev, A.I. and Muzgina, V.S., Kompleksnoe ispol’zovanie otkhodov i mestnykh materialov v tekhnologii zakladochnykh rabot (Integrated Use of Waste and Local Materials in Backfilling Operations), Almaty, 2002.

Anushenkov, A.N., Freidin, A.M., and Shalaurov, V.A., Preparation of Molden Solidifying Fill from Production Wastes, J. Min. Sci., 1998, vol. 34, no.1, pp. 86–90.

Krupnik, L.A., Shaposhnik, Yu.N., Shaposhnik, S.N., and Tursunbaeva, A.K., Backfilling Technologies in Kazakhstan Mines, J. Min. Sci., 2013, vol. 49, no. 1, pp. 82–90.

Freidin, A.M., Filippov, P.A., Gaidin, S.P., et al., Prospects of Technical Re-equipment in Underground Mines of the Metallurgy Complex in West Siberia, J. Min. Sci., 2004, vol. 40, no. 3, pp. 28–291.

Krupnik, L.A., Demin, V.F., Shaposhnik, Yu.N., and Shaposhnik, S.N., Selection of Rational Filling Process at Suzdal Mine, Alel, Vestnik KarGTU., 2011, no. 2 (43).

Krupnik, L.A., Shaposhnik, Yu.N., and Shaposhnik, S.N., Ways to Improve Strength Properties of Backfill Masses in Slice Mining Systems, Gorn. Zh. Kazakh., 2012, no. 6.

Karaev, O.S., Golik, V.I., and Magomedov, Sh.M., Standardization of Backfill Material Strength in Underworking Operations, GIAB., 2002, no. 5.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © L.A. Krupnik, M.Zh. Bitimbaev, S.N. Shaposhnik, Yu.N. Shaposhnik, V.F. Demin, 2015, published in Fiziko-Tekhnicheskie Problemy Razrabotki Poleznykh Iskopaemykh, 2015, No. 3, pp. 82–90.

Rights and permissions

About this article

Cite this article

Krupnik, L.A., Bitimbaev, M.Z., Shaposhnik, S.N. et al. Validation of rational backfill technology for Sekisovskoe deposit. J Min Sci 51, 522–528 (2015). https://doi.org/10.1134/S1062739115030138

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1062739115030138